RFID Tracking and Tracing Solutions

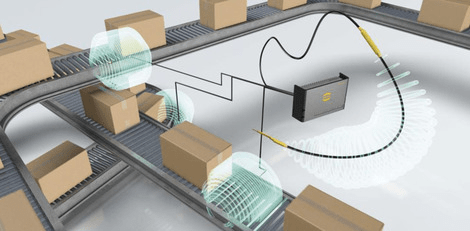

OPTIMAL CONNECTIVITY offers integrated UHF (Ultra High Frequency) RFID Solutions, a technology which can feed data to process control systems in vertically integrated production processes compliant with Industry 4.0.

Our UHF transponders are passive components, means they are maintenance-free. Nevertheless our transponders can be operates up to a a distance 2.5m from the RFID antenna and are also able transfer and store additional data to the reader.

Passive mode means that the system does not need an energy source on the side of the transponder. The system draws its energy only from the RFID reader.

Productions companies own big quantities of asset, machines, tool, raw materials, spare parts and products stock in warehouses.

- Where is the asset I’m looking for just now?

- When was this spare part purchased and by whom?

- Which tools do I need to install this spare part?

- When is next maintenance of my machines due?

RFID Solution

Our RFID solution allow automatic identification and location of any kind of assets. The RFID solution integrates with PLC- and ERP-systems, handheld devices, PCs, tablets, etc. in order to provide the right information at the right place.

Typical RFID solution elements

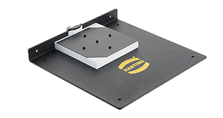

RFID RF-400 is a 4 channel RFID reader systems which allows the highly reliable identification and localisation of assets. It is equipped with Ethernet and digital interfaces to integrate into professional environment.

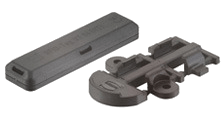

Customized RFID Transponder

We are offering custom-designed RFID transponder which are optimized for function on metal or even operate from inside metal cavities.

High Temperature RFID Transponder

Our high temperature transponder model are highly resistant against chemicals and operates in high temperature up to 210°C.

RFID Antennas

We are offering a range of RFID antennas which are designed for best function in challenging, metal containing environments.