OPTIMAL CONNECTIVITY offers metal-related services including CNC machining, laser cutting, water jet and plasma cutting. In our turnkey projects we often also design, build and install custom-design metal cabinet, housings for equipment like sensors, antennas, cameras and any kind of support elements like bars, antenna poles, brackets etc.

Bending, Welding

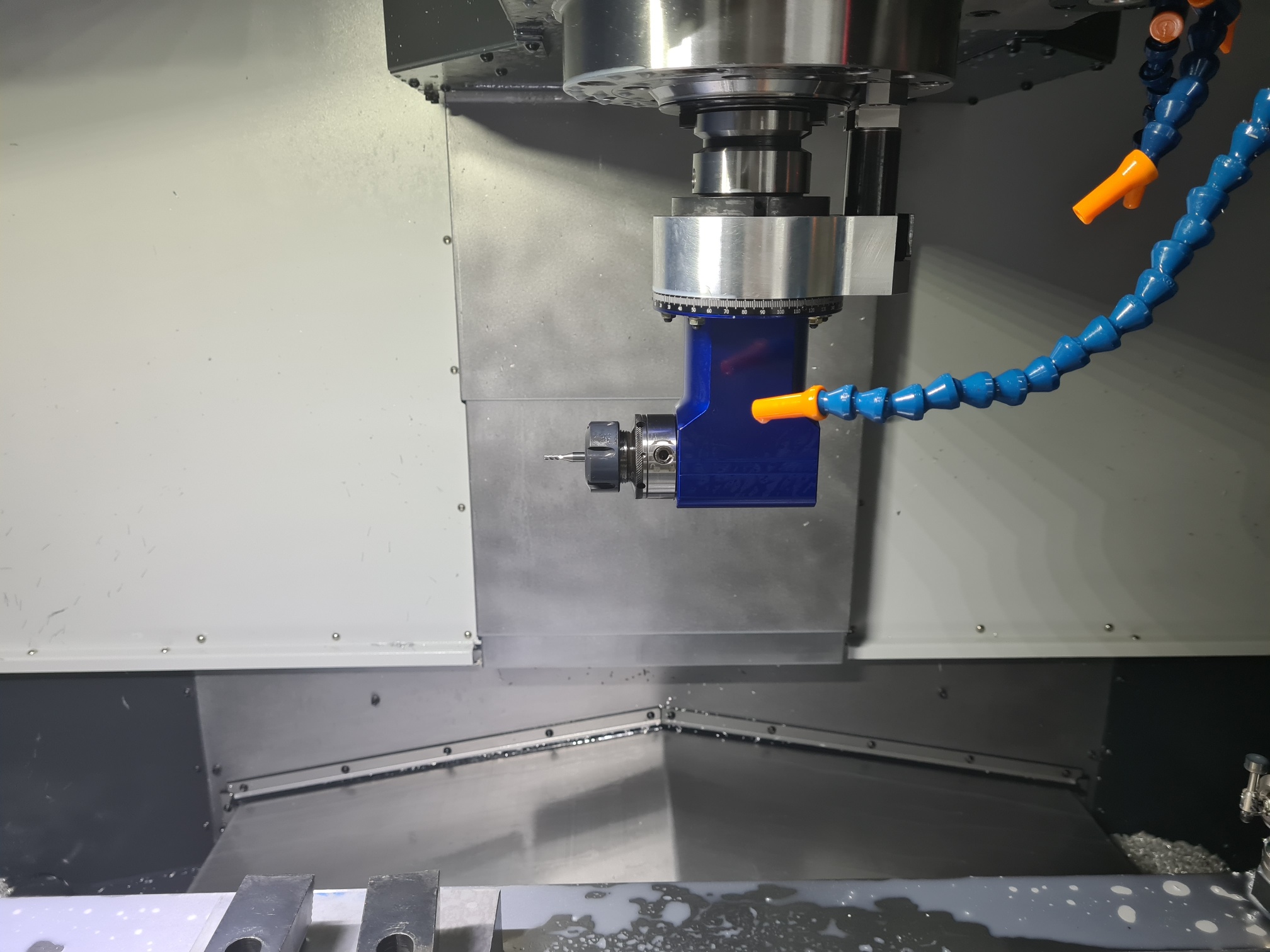

Our machining capability allows the size of objects ranging from a few millimeters up to meters. Depending on the requirements we use different grades of aluminium, copper, brass, mild steel and stainless steel types as raw material, sheets or blocks..

In high-precision manufacturing, we achieve an accuracy up to 1-2 micrometers. Besides metallic materials, we also manufacture parts made of polymeric materials like Teflon, Polyimide, Noryl, ABS, PE, ASA, PVC, Nylon, PBT and many more.

Together with our qualified and certified suppliers and service partners, we are offering CNC controlled metal profiling and sheet metalwork.

After cutting of material, typically CNC machining is required to achieve the requested surface quality for some items. For other items like cut to shape metal sheets, additional works CNC bending, welding and fabrication are steps to build like enclosures.

Final steps are surface treatment, galvanization (e.g. SurTec 650, gold, tin, silver plating) shot blasting, powder coating or wet painting all done according to the highest quality, environmental and health standards.

Our experts will assist you to design, co-design and manufacture your product.