Rapid 3D Prototyping Benefits

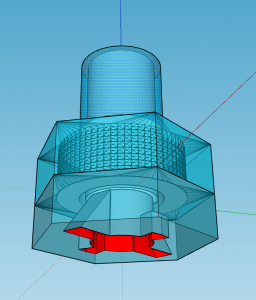

Creating mechanical prototypes is normally requiring lots of time and resources. In order to limit such overheads OPTIMAL CONNECTIVITY uses 3D design software during the development process. After reviews in CAD, 3D are transferred to the production process for creating the first prototype. Often we can use also 3D printing for a first haptic impression.

We use rapid prototyping for many of your most ambitious projects.

Presentation of multiple variants of the same prototype

Thanks to our development processes we typically produce multiple samples which are used in decision-making and costing process. Our digital 3D models can ve easily used in the seamless production process.

Often a mechanical model is the last step, prior to the model, other simulation software packages are used to develop the most suitable solution regarding, signal propagation, radiation pattern and RF behaviour throughout the frequency spectrum.

Functional prototypes

In our prototyping processes we try to achieve functional prototypes for pre-production product design and approval.

A data package also provides procurement department the flexibility in building and implementing their multi-source supply chain and build-to-order options.

The data package is maintained throughout the entire product life-cycle and records all essential details and updates of the product design. It includes the definition of the required design configuration and procedures to ensure adequacy of product or product-component performance. It includes all applicable technical data such as:

Short-Run Production

OPTIMAL CONNECTIVITY can quickly provide rapid prototype production quality to solve short-runs, small quantities (1-100) of a single design or multiple versions of numerous designs.

Prototypes are only the beginning of a product!

Our prototypes are used in many areas in our projects.

- Cable protection devices

- Special cable assemblies

- Antenna radomes

- Fiber optic closures

- Special cable divider

- Tools for manufacturing